work in process inventory is highest in

An important note to consider. There is no beginning inventory.

Industry 4 0 Will Make Production Systems Up To 30 Percent Faster And 25 Percent More Efficient And Elevat Industrial Supply Chain Infographic Systems Thinking

Work-in-progress WIP inventory is in the process to become finished goods it helps in earlier conversion to the finished goods and improves the turnaround cycle.

. Work in process inventory is highest in A. Work-in-process inventory often known as WIP inventory is pretty much its own field of expertise. Work in process inventory 60000.

Work in progress is the cost of unfinished goods in the manufacturing process. The standard work in process inventory definition is all the raw material overhead costs and labor associated with every stage of the production process. Most importantly its hugely important when youre considering a companys future growth potential.

Shortest processing time rule. The other two being raw materials and finished goods. In this latter case inventory essentially shifts directly from the raw materials inventory to the finished goods inventory with no separate work in process accounting at all.

Any raw material inventory that has been combined with human labor but is not yet finished goods inventory is work in process inventory. This essential category covers everything from manufacturing to construction. This inventory cycle repeats itself over and over during the year for manufacturers.

Keep in mind this value is only an estimate. Income Comparison of Absorption and Variable Costing Lets assume the following additional information for Harvey Company. Work in process is usually the smallest of the 3 most common inventory accounts.

The cost of work-in-process typically includes all of the raw material cost related to the final product since raw materials are usually. By Sarah Harris August 27 2021 5 min read. Assume Company A manufactures perfume.

Below are three techniques that can help an organization reduce their WIP. High average tardiness d. Company ABC utilizes a process strategy that involves highest volume of work in process inventory.

Work in process is the term used to describe partially completed goods which are typically turned from raw materials. For a more comprehensive example lets say you run a shoe brand with a beginning WIP of 100000. High work-in-process inventory c.

The WIP figure indicates your company has 60000 worth of inventory thats neither raw material nor finished goodsthats your work in process inventory. A work-in-progress WIP is the cost of unfinished goods in the manufacturing process including labor raw materials and overhead. Before the work cell equipment is sequenced.

Work in Progress WIP Inventory includes material that has been released from the inventory for the process but not yet completed and is waiting for a final inspection. Work in process WIP inventory refers to materials that are waiting to be assembled and sold. WIP or Work in Progress is a part of a companys overall inventory that has begun being processed but is not yet finished.

20000 units were sold during the year at a price of 30 each. The three types of inventories are direct material inventory work in progress inventory and the finished goods inventory where the direct material inventory includes the stock of raw material which the company has purchased for its use in production. WIPs are considered to be a current asset on the balance sheet.

For accounting purposes work in process is an asset and therefore is aggregated into the inventory line item on the balance sheet. First come first served rule c. 2robots that are flexible machines with the ability to.

Which strategy is Company ABC utilizing. Tracking of WIP levels and inventory is good manufacturing practice that ensures operations proceed smoothly. It doesnt take into account waste scrap spoilage downtime and MRO inventory.

This process works in a cycle that keeps on repeating during the year for manufacturing. Work in process inventory is highest in A. WIP Inventory Work-in-Progress is defined as the goods which are in different stages of production.

That makes it a part of manufacturing inventory see. Work in progress inventory is the cost accumulated to the goods that are partially completed and the. Fewest number of operations remaining rule b.

1vision systems that use video cameras and computer technology in inspection roles. WIP Levels and Forecasting. When work-in process is completed that product can finally be sold.

To calculate your in-process inventory the following WIP inventory formula is followed. WIP inventory example 2. And each subsequent sub-process throughout the factory adds additional value.

Sometimes the accounting system accounts for the semi-finished goods in this category. These items are typically located in the production area though they could also be held to one side in a buffer storage area. Work in progress accounting involves tracking the amount of WIP in inventory at the end of an accounting period and assigning a cost to it for inventory valuation.

In the context of sequencing the _____ tends to maximize resource utilization. 3 Techniques to Reduce WIP Work in Process in Manufacturing By Shmula Contributor Last Updated August 9 2018 Work in Process WIP in some cases also. In the new year you spend 150000 on manufacturing costs.

A Mass customization b Process focus c Repetitive focus d Product focus. Company ABC utilizes a process strategy that involves highest volume of work in process inventory. Your manufacturer also produced 5000 pairs of shoes each costing around 30 to produce on average.

Now lets compute net operating income using both. A large quantity and large variety of products are produced in. Top 3 Types of Inventory.

Work In-process Inventory Example. Technologies that are more involved with the processing of inventory but still could be considered to handle inventory include. In the accounting department of manufacturing companies the in-process inventory is an important process where accounting for the value of in-process inventory is done.

As raw materials and components are consumed they gain value because they have incurred some labor and overhead. Raw materials are converted to work in process inventory and then converted to finished goods. Now lets compute net operating income using both absorption and variable costing.

The last quarters ending work in process inventory stands at 10000. Work in process inventory is highest in A. Ending WIP Inventory Beginning WIP Inventory Manufacturing Costs- Ending WIP Inventory.

The best case is to establish the lowest WIP levels and batch sizes so that good operational flow is maintained. In the accounting department of manufacturing companies the in-process inventory is an important process where accounting for the value of in-process inventory is done. So your ending work in process inventory is 10000.

After the work in process inventory has completely been manufactured it can be sold to a customer as a finished good and is no longer considered a work in process. Calculating work in progress inventory. Work-in-process inventory is materials that have been partially completed through the production process.

High average flow time.

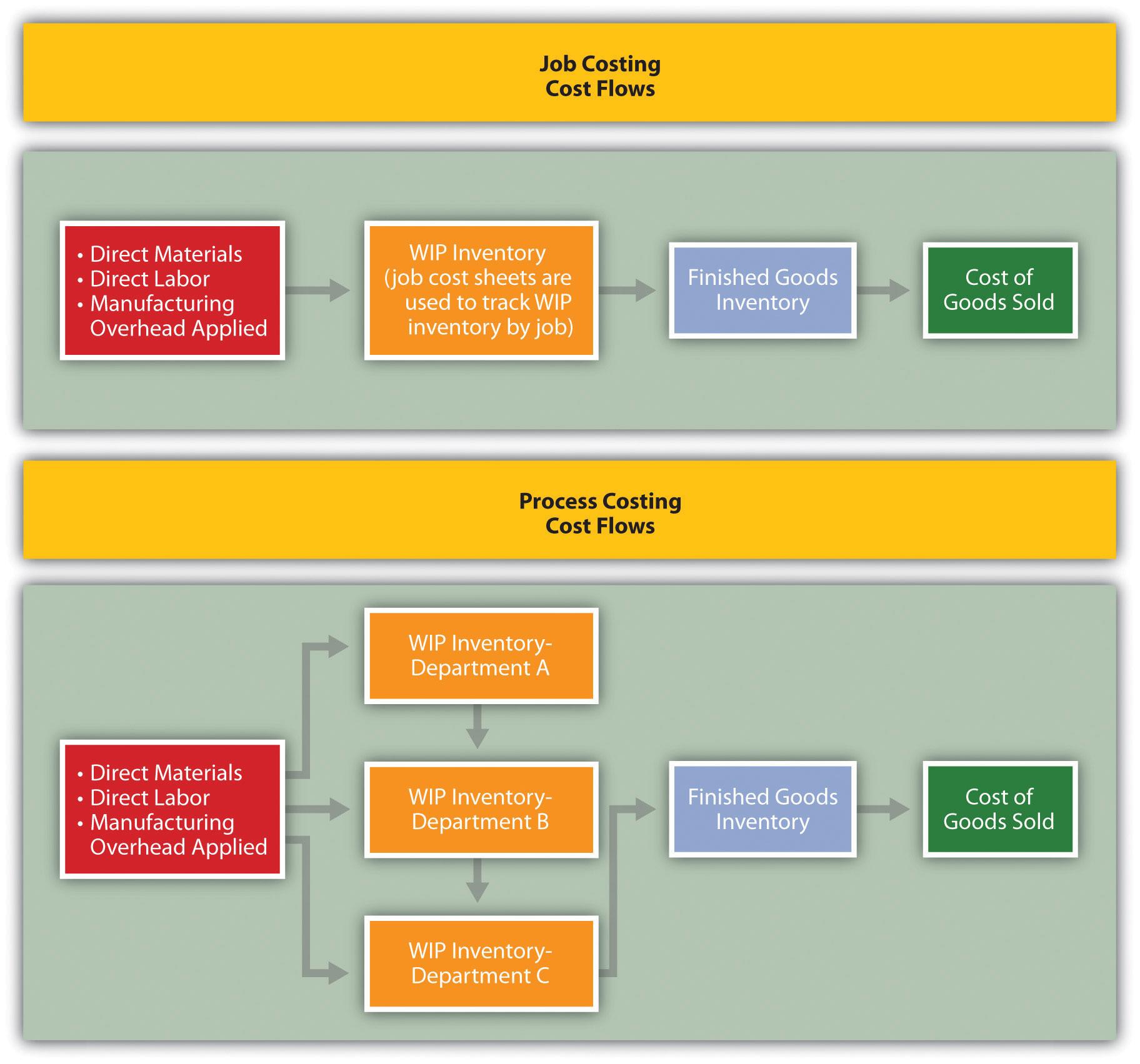

Comparison Of Job Costing With Process Costing

It S Still A Sellers Market Infographic Infographic Marketing Things To Sell Infographic

Inventory Classification Youtube Inventory Classification Work In Process

Work In Process Inventory Formula Wip Inventory Definition

Work In Process Wip Inventory Guide Formula To Calculate

Wip Inventory Definition Examples Of Work In Progress Inventory

Inventory Costing Bookkeeping Business Accounting Basics Inventory Accounting

What Is Work In Process Wip Inventory Definition Formula And Benefits Article

Learn How To Do Dropshipping Dropshipping Suppliers Dropshipping Inventory Cost

Managerial Accounting Job Order Process Costing Accounting Accounting Jobs Managerial Accounting

What Is Inventory Management Supply Management Logistics Management Visual Management

Managerial Accounting Process Cossting Accounting Education Accounting Process Managerial Accounting

Inventory Process Data Collection Reconciliation Inventory Management

8 Wastes Downtime Using Lean Six Sigma Goleansixsigma Com Lean Six Sigma Process Improvement Business Process

Work In Process Inventory Formula Wip Inventory Definition

Inventories Far Cpa Cpa Inventory Cpa Exam

What Is Work In Process Wip Inventory Definition Formula And Benefits Article

Benefits Of Business Process Automation Business Process Automation Business Automation